All industrial production that uses energy will be a source of Greenhouse Gas (GHG) emissions, if not entirely powered from renewable sources. Especially for upstream oil and gas production where the dominant energy source is not renewable.

However, it is possible to keep the emissions footprint as small as possible through operational optimization. When we discuss emissions, it is often carbon dioxide (CO2) emissions, as they dominate over other emissions such as Methane (CH4) and Nitrous oxide (N2O). Methane is the second after carbon dioxide (CO2), accounting for about 20 percent of global emissions. However, Methane is more than 25 times as potent as carbon dioxide at trapping heat in the atmosphere. This is an important consideration for the future! In general terms, the composition of these emissions, for the UK for example, has stayed relatively constant over the years with fuel combustion roughly at 70%, flaring at 25%, and venting 5%.1

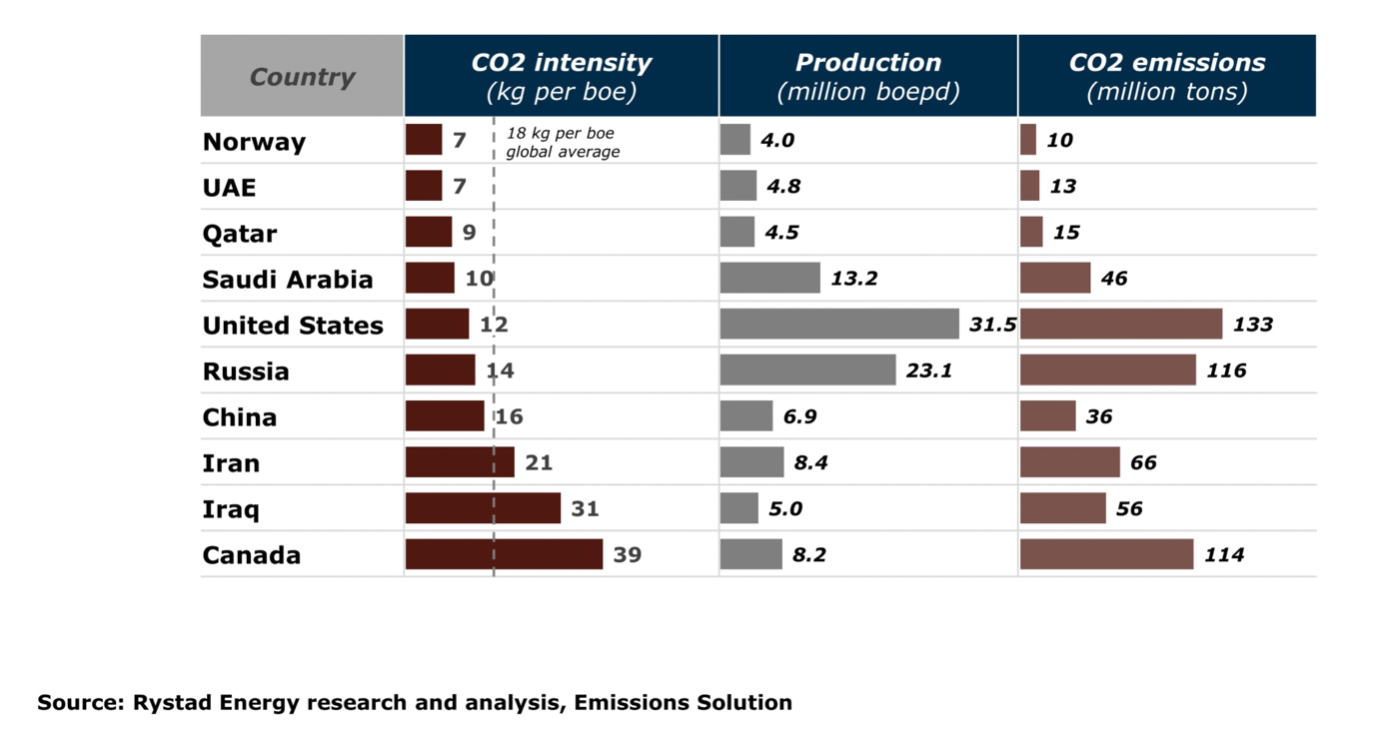

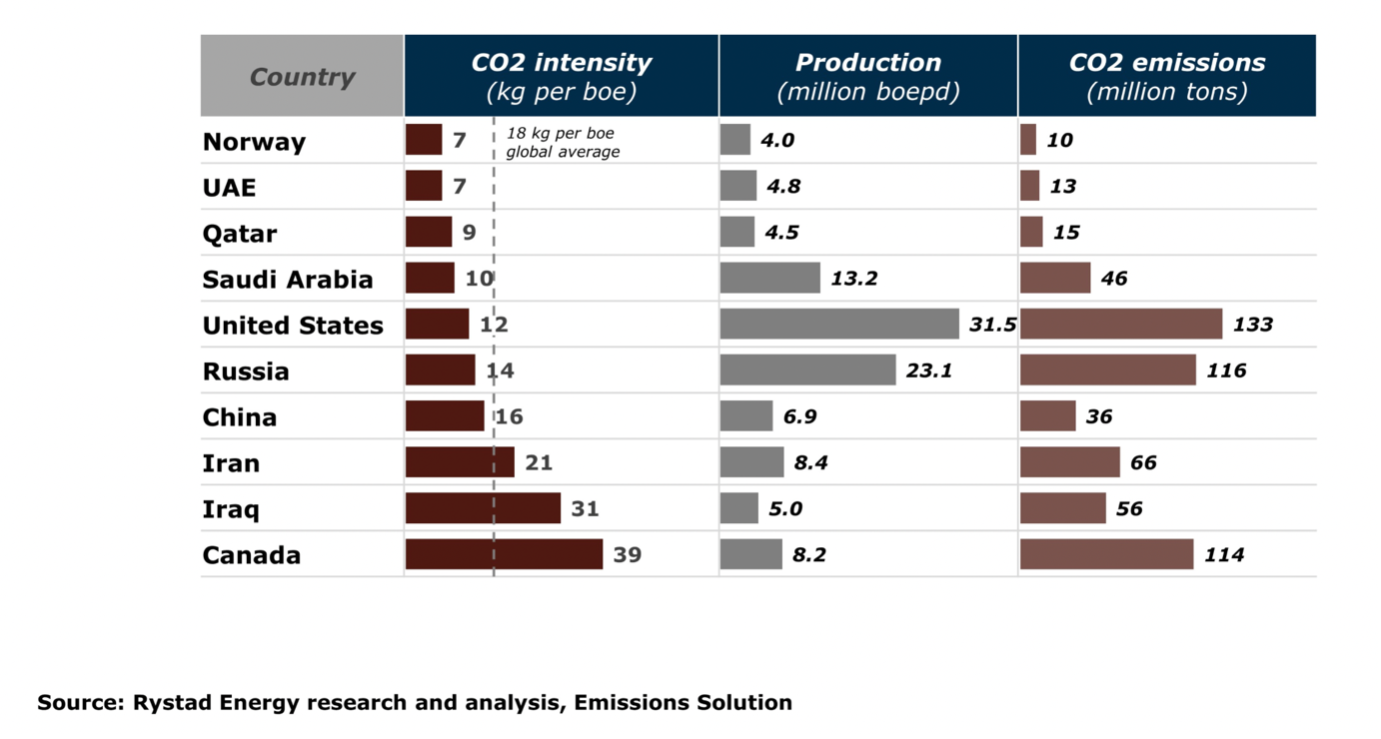

A comparison with regards to CO2 emission for the top ten oil and gas producing nations was recently made available by Rystad Energys’ Emissions solutions.2

The differences are huge, with Norway, UAE, Qatar, and Saudi Arabia having a CO2 intensity below 10 kg per barrel of oil equivalent (boe). produced compared to an average of 18 kg per boe, and the worst case 39 kg per boe. Some of these differences can be explained by the very nature of the oil extraction process where production from oil sands is the most energy demanding process. Still, some of the difference is no doubt due to the ban of flaring (except when needed of safety reasons) and CO2 taxation in some regions. Two major factors to minimize emissions mentioned in the Rystad energy report are stable production and reduced flaring. These operational strategies will always be important regardless of how and where the oil and gas is produced. Therefore, one simple conclusion is to start by targeting stable production.

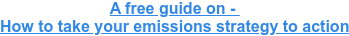

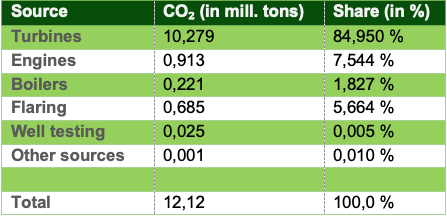

The Norwegian Petroleum Directorate has made an interesting table on sources of CO2 emissions to air from upstream oil & gas production in Norway 20203:

Knowing that we need to ensure stable production and reduce flaring to be able to reduce emissions is a great starting point. But how can we implement this in our strategies?

Here are 5 ways to reduce emissions by improving operations

1. Start by choosing the main contributors

The main contributors will be the turbines (If not powered/electrified by hydropower from shore). A solution might be to simply stop the turbines, but the reality is that they are needed to maintain production if electrification is not feasible.

A prioritized list might be:

- Stable production is most energy efficient (best efficiency point or BEP)

- Avoid shutdown and flaring

- Identify further contributors

You could argue that venting should also be on the list, and that may very well be the case. However, the ratio of flaring to venting is approximately 10:1 in UK. In Norway, the same ratio is approximately 1:4.4

2. Optimize the use of main contributors

A common understanding of the relative emissions from each contributor is important. We must establish a best practice Standard Operational Procedure (SOP) that includes clear objectives on how to use the equipment under each operational mode.

3. Ensure that the best practice operation is shared among the operations teams

Day-to-day operation comes down to each individual control room operator. Updated standard SOPs that cover how to deal with deviations is of paramount importance. Ensuring that the SOPs are readily available and preferably mode-aware will be a positive contribution toward sharing a common best practice.

4. Create a culture of reduced emissions

The operator’s job is not done when production is stable and efficient. That’s when the real work begins, by optimizing the energy consumption and reducing emissions. In the past, the operators have been trained to prioritize safety, then production. However, with sustainability at the top of everyone’s agenda, the priority may need adjustment to safety, production, and emissions. This expectation is also in line with the UK Oil and Gas Authorities’ expected behavior and good practice from the industry.6

5. Ensure that the culture includes continuous improvement

We have learned from the past that maintaining and improving a safety culture involves creating visibility and learning from unwanted incidents. This practice needs to be adopted to include emissions also. Near misses which has (or might have had) emissions impact, needs to be captured and SOPs improved accordingly. This approach also needs to be adopted across assets and fields.

We foresee that driving operators’ priority and KPIs towards emissions reduction could be a vital step to making these strategies work.

Sources: