Kairos and Equinor are cooperating to improve real-time situational management in the control room at Johan Castberg with the use of advanced AI and functional modeling.

Equinor is the leading company on the Norwegian continental shelf. It is an energy company with 21,000 colleagues producing energy in more than 30 countries worldwide. Equinor is committed to security, equality, and sustainability. The company is now building an even more global business with focus on energy needs for the future.

The Johan Castberg field is situated approximately 100 kilometers northwest of the Snøhvit field. The water depth is 370 meters. The Johan Castberg field development project's resource base consists of the three oil discoveries Skrugard, Havis, and Drivis. The development concept is a production, storage, and offloading vessel (FPSO), with additional subsea solutions, including 18 horizontal production wells and 12 injection wells. The production capacity is approximately 200,000 barrels of oil per day, and the expected lifetime of the field is 30 years. Johan Castberg will serve as Norway’s most northern oil- and gas-field. The project is currently in full development and the expected production start-up is 2022. The Johan Castberg oilfield in the Barents Sea is located in an area with some of the roughest weather conditions in the world. New and optimized solutions are therefore used in this project to reduce cost and improve regularity and safety.

KAIROS TECHNOLOGY – AN ARTIFICIAL INTELLIGENCE COMPANY

Kairos Technology is a supplier of a world-leading Artificial Intelligence package, supporting the control room operators to superior insight into any abnormal situation. We work closely with E&P companies and operators to increase insight with accelerated and more targeted responses. This is leading to improved plant performance, increased safety, and reduced emissions.

Kairos Technology was founded in 2014 and is developing applications based on the theories on Multilevel Flow Modelling (MFM), a theory invented by Morten Lind, (Professor Emeritus, Senior Researcher) at the Technical University of Denmark (DTU).

A paradigm shift for optimizing decision-making in the control room

OUR MISSION

Our mission is to optimize production and improve production effectiveness by providing a software that will reduce effects of abnormal situations, avoiding shutdowns, and provide real-time decision support when abnormalities occur in complex industrial systems. Kairos Technology is a software company passionate about creating superior performance of plants through real-time insights.

OUR EXPERTISE

Our expertise covers the entire processing system from the field instruments to advanced processing functions. We create advanced cloud applications with streamed real-time data from sensors on the production unit. We understand the complex engineered systems, the needs of the control room operator, and we know the different system elements operators handle on a daily basis.

OUR VISION – ASSIST OPERATORS TO PERFECTION

OUR TECHNOLOGY

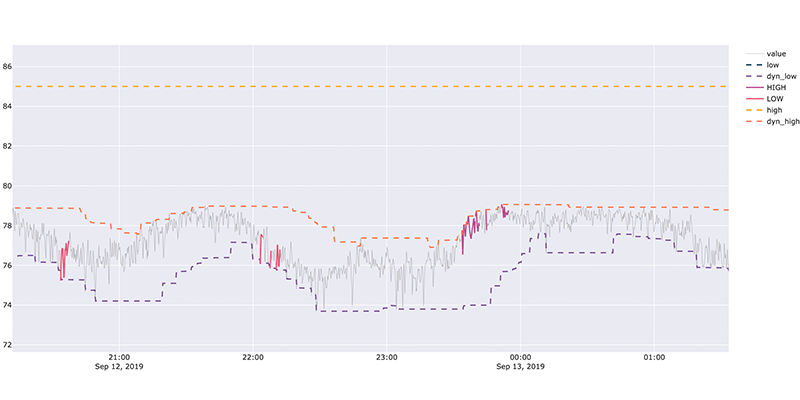

Kairos CRA combines deterministic modeling with deviation propagation and Artificial Intelligence (AI) algorithms, with streaming real-time data from the various sensors on the plant (e.g. data from the control and safety systems).

Kairos CRA uses process measurements to detect abnormalities and provide the operator with the root cause for the incident, the consequences it may lead to, and suggests counteractions to the control room operators.

HAZARD PREVENTION

Kairos Technology provides you with software to capture all information, skills, and experience on your specific processing system, including all fault scenarios in a functional model. During operations, Kairos CRA uses the functional model to provide the control room operators with the information they need to best handle the situation in the process system. The information is provided to the operators in the control room and information is presented with the early stages of abnormalities to help prevent disturbances.

TARGET FOR THE USE OF ARTIFICIAL INTELLIGENCE

Johan Castberg FPSO is targeting a virtual control room assistant to support operators with situational awareness, optimization of production safely, and reduction of carbon footprint. Kairos is a virtual assistant that will assist the operator in critical situations. Kairos will help find root cause for abnormalities in the process system and provide the operator with the solution when an abnormality occurs. This tool can be used as a guide to locate problem areas quicker, understand future propagation on your plant, and understand how to intervene in the abnormal situations.

THE COOPERATION WITH EQUINOR

Equinor has been part of the development of Kairos CRA as a member of the Reference User Group, consisting of major E&P companies and land-based processing industry since January 2018.

The cooperation with Johan Castberg will include the main Kairos CRA for use in the central control room and further development of the software in line with Johan Castberg’s strategy. The steady state support will be enhanced to support mode changes, such as start-up and shutdowns.