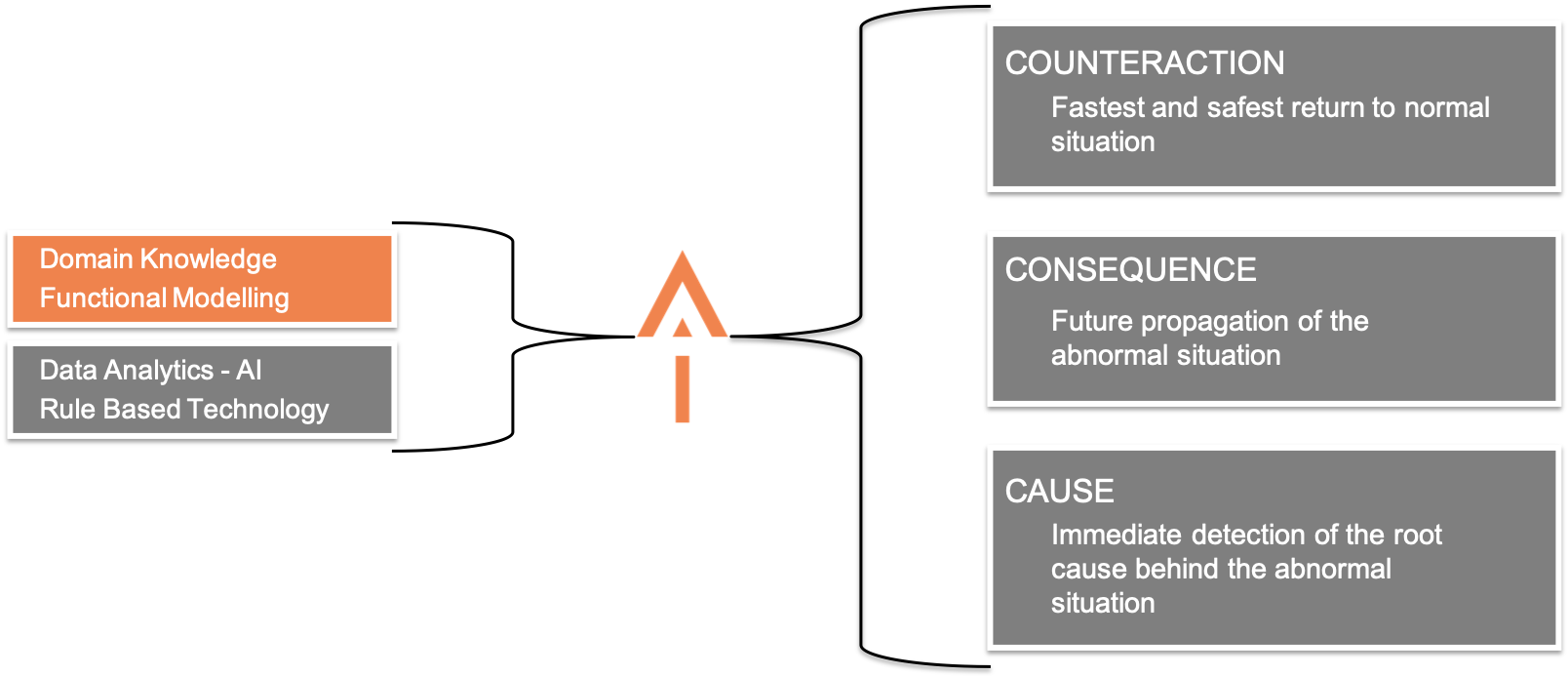

The understanding of root causes is important to ensure that a fault is dealt with in the most effective manner to avoid escalation and reduce the risk of the fault happening again.

When we rely on many interacting systems to achieve a goal, the resulting complexity can make it extremely difficult to identify the cause behind an unexpected problem. This is true in most industrial applications and increasingly true for the energy and processing industries. Plants become more complex and understanding root causes and propagation of faults is challenging and often very time consuming.

Our vision is to assist operators to perfection and we are currently working in two different, but tightly connected areas:

These two objectives both aim to improve plant safety and performance but require different response times and different levels of detail. Control room operators must reach situational awareness within seconds to be able to avoid loss of production. The detail level needs to match the requirements for fast decision making. When it comes to the engineering tasks, the level of detail is more important. However, being able to analyse scenarios quickly in design review meetings is still important to engage effectively with experts and experienced staff. For example, the use of process simulators is impractical in a Hazop meeting context and only feasible for a small number of scenarios during design or operational support.

The best solution would be to find a way to build a digital twin where we can address both physical issues combined with human and organisational causes. Today we are totally dependent on the expertise and experience of the control room operators and engineers. What if we could combine both the explicit knowledge from design and combine with the tacit knowledge built through experience?

If the control room operators gain instant access to the plants combined process knowledge as a disturbance start to develop, the responses will be more targeted for optimized production and reduced downtime.

Incidents that develop into disturbances and even total loss of production always involve risks. Instant overview of likely root cause and consequences will reduce the risk of misunderstanding and taking wrong decisions and actions.

The explicit process or the exact knowledge about the design and operation of a plant is documented. However, the documentation may be difficult to find and understand when it is needed.

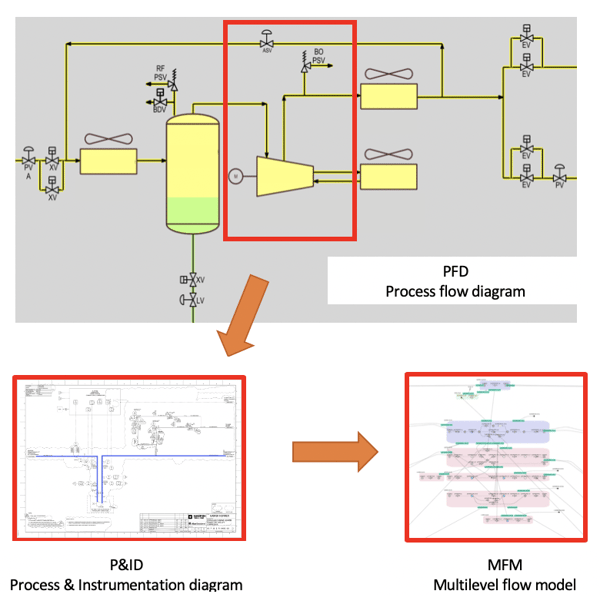

Multilevel Flow Modelling (MFM) is a theory invented by Morten Lind, (Professor Emeritus, Senior Researcher) at the Technical University of Denmark (DTU).

Multilevel Flow Modeling (MFM) is a methodology for functional modeling of industrial processes on several interconnected levels of means-end and part-whole abstractions. The basic idea of MFM is to represent an industrial plant as a system which provides the means required to serve purposes in its environment. MFM has a primary focus on plant goals and functions and provide a methodological way of using those concepts to represent complex industrial plant.

- Morten Lind

Kairos technology is built upon this theory combined with the latest developments within AI such as data analytics, rule-based reasoning and machine learning.

The technology embedded in our Kairos products combined deterministic modelling with deviation propagation analysis and artificial intelligence. The digital twin utilizes human experience along with the physical design parameters to capture and make use of tacit knowledge (embedded in human mind) and explicit knowledge from design parameters.

CTA

The workbench is our cloud-based toolbox for building, maintaining and testing the multilevel flow models. An extensive library covering the most common process equipment has been made and hence the modelling is fast.

As the models are a combination of modelling the process and adding experience, the library will be constantly improved, and learnings transferred between sites.

The MFM model may be used to introduce hypothetical errors and returns root causes and forecasts consequences. The model is used as a basis for two different products.