During the past few years, our understanding of how humans use and produce energy and how this is impacting the environment, has led to a number of new energy systems being developed and put in place. The solutions to the challenges of emissions like CO2 and NOx and the following climate change will be diverse. It is also well known that we do not have much time to stop the increasing trend, so we need to both attack the current emissions and at the same time implement new long-term zero-emissions solutions. Lead-time to get the new systems in place is of vital importance.

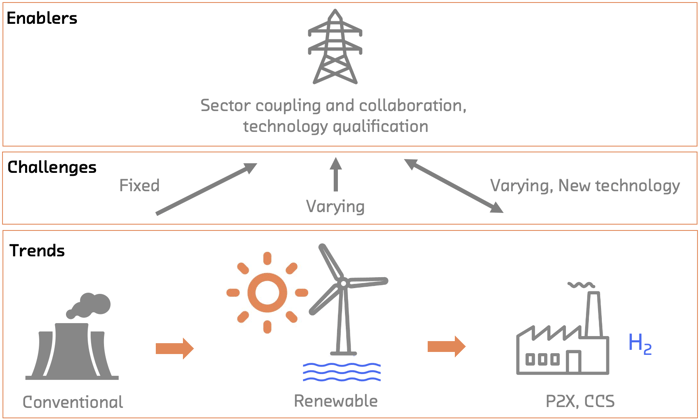

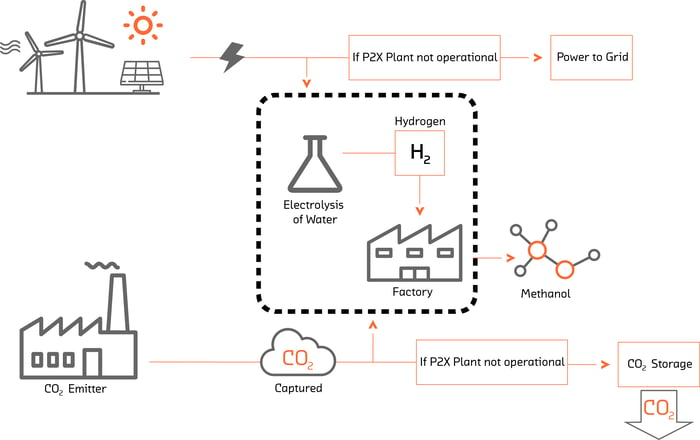

New renewable energy sources such as wind or solar power are being added into the energy mix introducing new problems related to fluctuations. There is a need to store the energy and hydrogen, methanol and ammonia are possible solutions. The new energy systems cover the complete value chain from energy production, transportation storage, and the sector, coupling between the new and existing players.

Efficient sector coupling solutions are an enabler for decarbonizing, where energy storage systems outside of the electrical sector are used to balance the fluctuations in supply dependent renewable energies, such as solar power and wind. The benefits of the holistic views of the energy systems are:

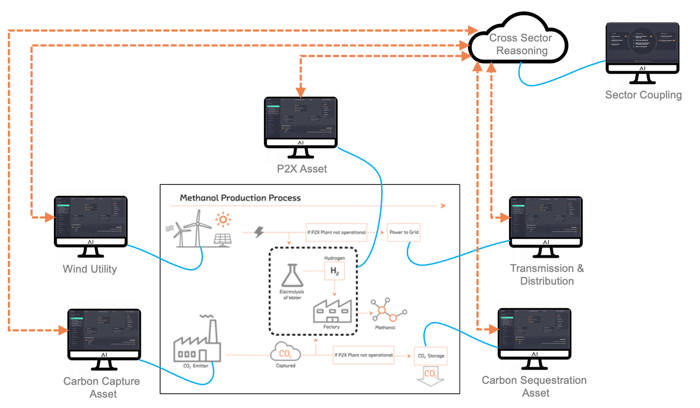

Kairos Technology offers engineering-, monitoring-, and operator decision support solutions based on qualitative explainable AI technology, which accelerates the discovery of undesirable phenomena in plant production processes. The benefits are increasing production efficiency by 3-7% in process plants, reduced energy consumption, reduced emissions, and reduced maintenance cost by more than 10%. One unique feature of our digital twin is that it may be used for process systems, mechanical systems and electrical systems individually, or in combination within sector coupling solutions.

This enables a holistic sector-wide approach, where failure modes are detected on any system level instantaneously, along with consequence propagation and suggested mitigation(s).

We can take examples from methanol synthesis of green H2 and nitrogen or captured CO2 in Power to X facilities. As Power to X facilities scale up, more sub-systems will exhibit sector coupling challenges, e.g. varying wind power input to the electrolysers in island mode, fluctuation in feed gas supply (nitrogen or CO2) and local grid stability that is depending on main grid connection.

Superior situational awareness leading to fast responses to deviations returning the plant to normal state require immediate understanding of root causes and failure modes on individual systems, with consequences propagation analysis and recommended mitigation.

Operational value to each energy system:

On a cross sector level, the reasoning will enable real-time notification and early warning between the different parts of the integrated energy systems. As an example, it will be of paramount importance to get a pre-warning that the ammonia plant will shut down transferred to both for the distribution and transmission control.

The solution available is based on our product Kairos - Control Room Assistant.

Before introducing novel energy technologies, it is vital to ensure the integrity of the new process design. All complex plant designs will be subject to hazard and operability studies where the planned process is subject to a structured process, which will evaluate that the required safeguards are in place in order to manage identified risks to personnel and equipment.

For existing and proven technology, the experience of failure modes is taken into account when designing plants. Familiar processes and plants that have been in operation for years will have experienced failures and problems that have been rectified and improved. Plant design of novel technologies lack the operational experience, and this poses an additional unknown risk by itself. Obviously, the target is to avoid the risk with the appropriate level of instrumentation and safeguards in place.

Using a HAZOP (Hazardous and Operability study) work process is a de-facto standard within high-risk complex plant design. Our software tool HAZOP Assistant will significantly reduce the cost of HAZOPs and ensure learnings of failure modes are captured and reused for the operations and future re-HAZOPs. Kairos HAZOP Assistant will:

Click here to learn more about Kairos - HAZOP Assistant

Kairos Technology is a software company that develops innovative and disruptive technology within the energy industry.

Phone: +47 952 91 478

E-mail: info(a)kairostech.no

Address Norway:

Kanalsletta 4, N-4033 Stavanger

Address Denmark:

DTU Science Park, Diplomvej 381, DK-2800 Lyngby