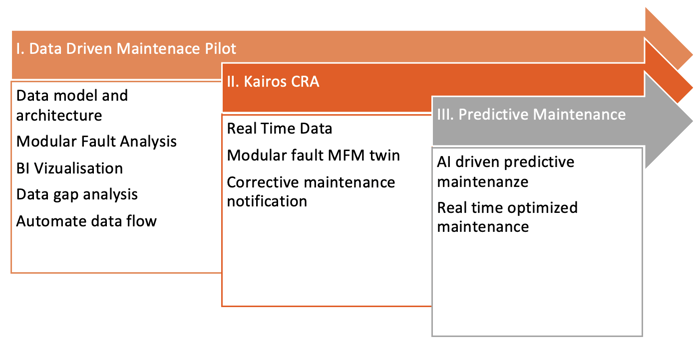

Our vision is to achieve data-driven modular predictive maintenance from historical data enhanced with a real-time process knowledge digital twin, based on multi-level flow (MFM) modelling to achieve real-time optimized maintenance.

One of the most important factors when reducing cost during design and manufacturing is to use standardized proven components. This is obvious to most of us, and we instinctually start looking for modules we can reuse when we start a new design process that involves creating something new. The examples are numerous. One example is cars, where you can even find different car brands with the same engine. When we start developing a new software solution, the first step is to find existing solutions and libraries. The benefits of using this approach are the known strengths and weaknesses, and the reduced time to engineer, build, test, and operate.

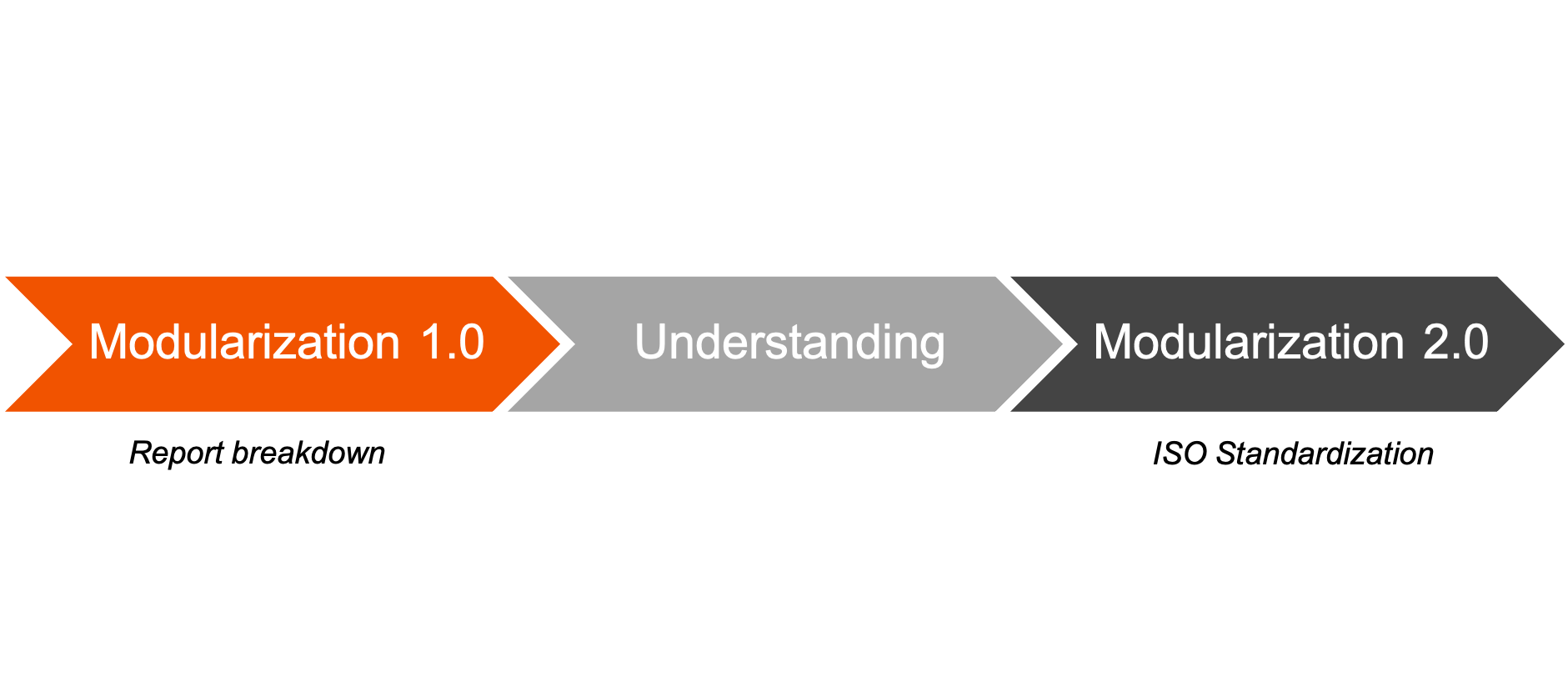

Why not take it one step further and use modular thinking and breakdown within maintenance? We know and have demonstrated that using a modular approach can greatly reduce the maintenance costs of complex processes and systems. Data-driven predictive maintenance has been proven to have a potential of reducing the corrective maintenance by 20-40% on its own.

Establishing a data-driven maintenance process consists of applying data analytics to historical maintenance data and include captured sensor data in real-time, by using algorithms for predictive maintenance. Today it’s available from combining “off-the-shelf technology” that multiple companies may provide. So why are the concepts not more widely used? There are a number of key factors, such as: lack of data quality, lack of data reporting, the list could be long.

Kairos Technology, with its close connection to the Danish Technical University (DTU) represents a different approach when it comes to maintenance optimization:

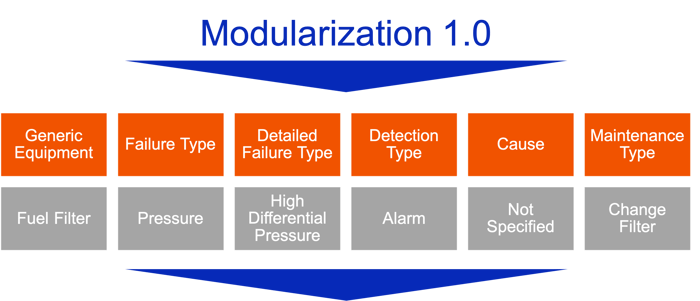

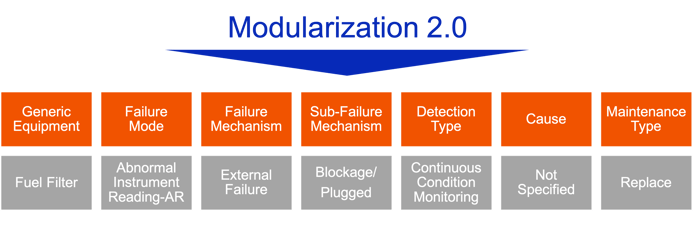

Example of modularization of failure modes

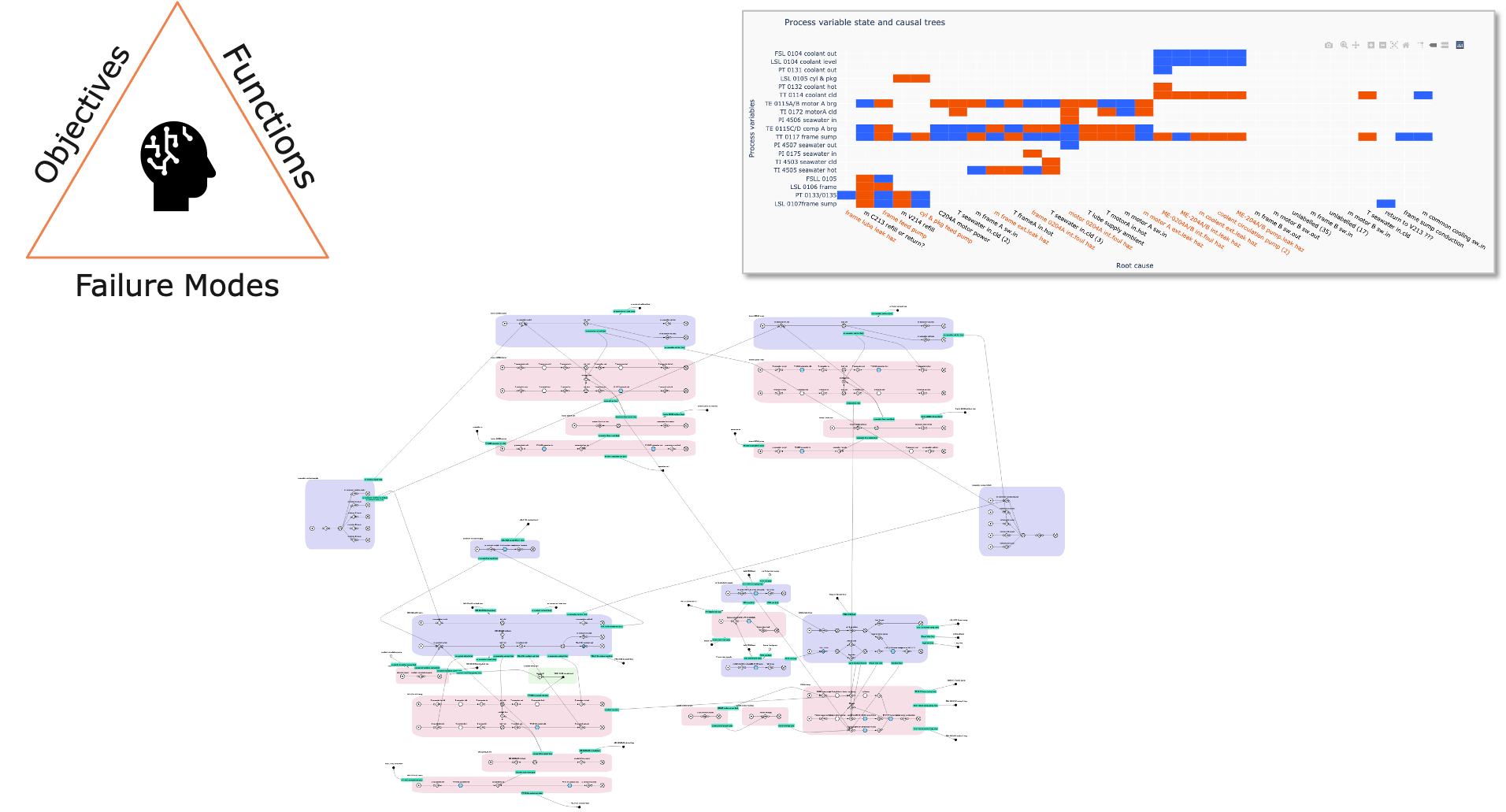

Combining data driven predictive maintenance with workflow modularization principles and the unique MFM technology from DTU, will enable explicit representation of failure modes and their consequences. This opens opportunities to prioritize and effectively execute maintenance based on real time situational awareness.

Qualitative physics modelling to identify failure modes

The digital operational twin established for the Control Room Assistant (CRA), currently available, can be supplemented to become a digital maintenance twin. The process digital twin will be enhanced and used to capture key parameters for improved the maintenance based on real-time process sensors. This way, we utilize the proven in-use software product called the Control Room Assistant (CRA) for capturing additional data and improving the overall operation and maintenance process.

Data-driven predictive maintenance based on workflow modularization has been proven to have a potential of reducing the corrective maintenance by 20-40% on its own. Additionally, the Control Room Assistant has a potential of 3-5% increased production efficiency.

Combining the two approaches will ensure that situational awareness performance and failure mode risks are utilized to predict maintenance needs and drive operation, to extend the current maintenance intervals.

Improved situational awareness to the operation and maintenance teams will enable increased cross-functional collaboration and optimization of workflows. The results are safer operation, improved production efficiency, and optimized production at the lowest possible maintenance cost, by providing timely responses to developing incidents and targeted operational maintenance.

Kairos Technology is a software company that develops innovative and disruptive technology within the energy industry.

Phone: +47 952 91 478

E-mail: info(a)kairostech.no

Address Norway:

Kanalsletta 4, N-4033 Stavanger

Address Denmark:

DTU Science Park, Diplomvej 381, DK-2800 Lyngby