Situational awareness is a critical element for operational success, especially in industries with complex and high-stakes environments like nuclear, hydrogen, ammonia, oil & gas and petrochemicals. By leveraging data analytics, companies can enhance their ability to monitor, predict, and respond to events with precision and speed. But how exactly can data analytics improve situational awareness for operators? Let's explore.

Understanding the Core Concepts

At its heart, data analytics refers to the process of examining raw data using qualitative and quantitative techniques to extract meaningful insights. Within a control room setting, the objective is clear: empower operators to make faster, better-informed decisions.

Situational awareness, as defined by Mica R. Endsley in 1995, is “the perception of environmental elements and events concerning time and space.” Put simply, it’s about understanding what’s happening now and projecting how future events will unfold.

However, achieving true situational awareness requires more than just collecting vast amounts of data. It demands the right tools, expertise, and visualization techniques to transform raw information into actionable intelligence.

The Power of Data Analytics for Process Safety

Data analytics is already a proven tool in driving efficiency and performance. The technology can be traced back to the 19th century, but its evolution into big data analytics has only been made possible by advancements in computing. Machine learning, predictive analysis, and data mining have elevated analytics to a whole new level.

For example, predictive maintenance uses historical data to forecast equipment failures, reducing downtime and optimizing resource allocation. Similarly, data analytics helps identify operational risks by uncovering patterns within data sets. These applications aren't just theoretical; they’ve already been implemented across industries with significant success.

When it comes to situational awareness, however, the challenge lies in applying these tools in real-time. While current data analytics excels at analyzing trends and generating longer-term insights, its application in live operations is still evolving.

Applying Data Analytics to Real-Time Operations

The control room, where decisions often need to be made in seconds, demands tools capable of real-time insights. Alarm management systems, for instance, are an early step in this direction. These systems process and analyze alarm data to present critical information in a user-friendly format, enabling faster, more accurate decision-making.

However, using data analytics in real-time isn’t without limitations. Many systems today are optimized for back-office teams operating on longer timeframes, such as hours or days. To bridge this gap, companies must integrate advanced data visualization and focus on filtering out irrelevant information. This requires a collaboration between data analytics professionals and domain experts who understand operational processes.

Combining Data Analytics with Advanced Models

The future of situational awareness in the industry lies in the integration of data analytics with deterministic modeling. While data analytics excels at learning from past events, deterministic models simulate how specific scenarios may unfold. By combining the two, companies can create powerful tools to anticipate abnormal situations and assess their potential impacts.

Dynamic process models offer another promising avenue for accurate predictions. Though often slower, these are ideal for back-office support teams handling more complex scenarios. For time-critical decisions in the control room, a hybrid approach—blending real-time data analytics with streamlined process models—is key.

Kairos Technology's Control Room Assistant is a prime example of how innovation can push these boundaries. By consolidating data from diverse sources into a single, intelligent platform, it enhances operators’ ability to assess evolving situations instantly and respond efficiently.

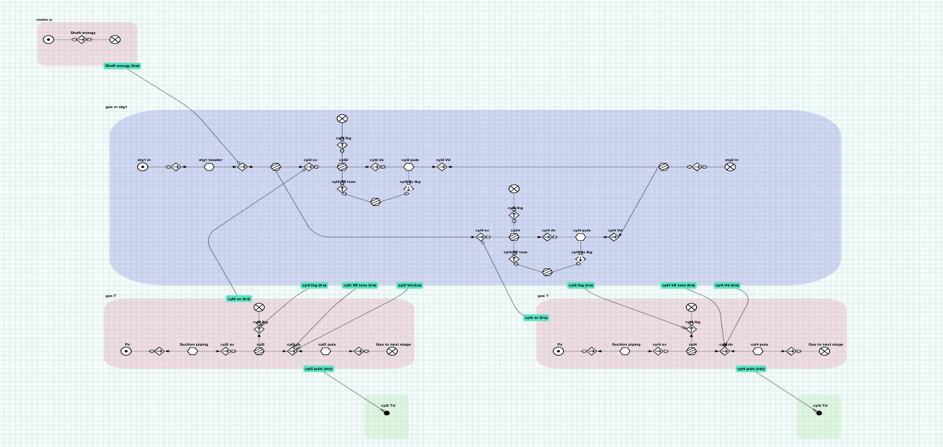

(MFM) Process Model

The Path Forward

The industry is poised for a transformation, with increasingly larger data sets and shared data systems becoming the norm. Yet, it’s crucial to recognize the limits of predictive analytics. Data analytics can only predict future outcomes based on what has occurred in the past. To overcome this, the integration of data analytics with expert domain knowledge and advanced modeling will unlock new opportunities.

Investing in accurate visualization tools and fostering collaboration between analytics teams and operational staff will further enhance situational awareness. These technologies are not just tools for today but vital components of the future, where predictive insights and real-time decision-making combine seamlessly.

Closing Thoughts

Improving situational awareness with data analytics is no longer just a theoretical concept; it’s an actionable strategy. By combining the strengths of data analytics, deterministic modeling, and human expertise, companies can unlock significant gains in operational safety, efficiency, and performance.

While the tools and methods continue to evolve, the end goal remains clear—to provide operators with the insights they need to act decisively and maintain a safe, effective working environment. For complex industries, achieving this level of situational awareness isn’t just an advantage; it’s a necessity.

At Kairos Technology, we’re leading the charge in this transformation. With innovative solutions like the Control Room Assistant, we’re helping companies stay ahead of the curve. The future of situational awareness is bright, and the possibilities are limitless.