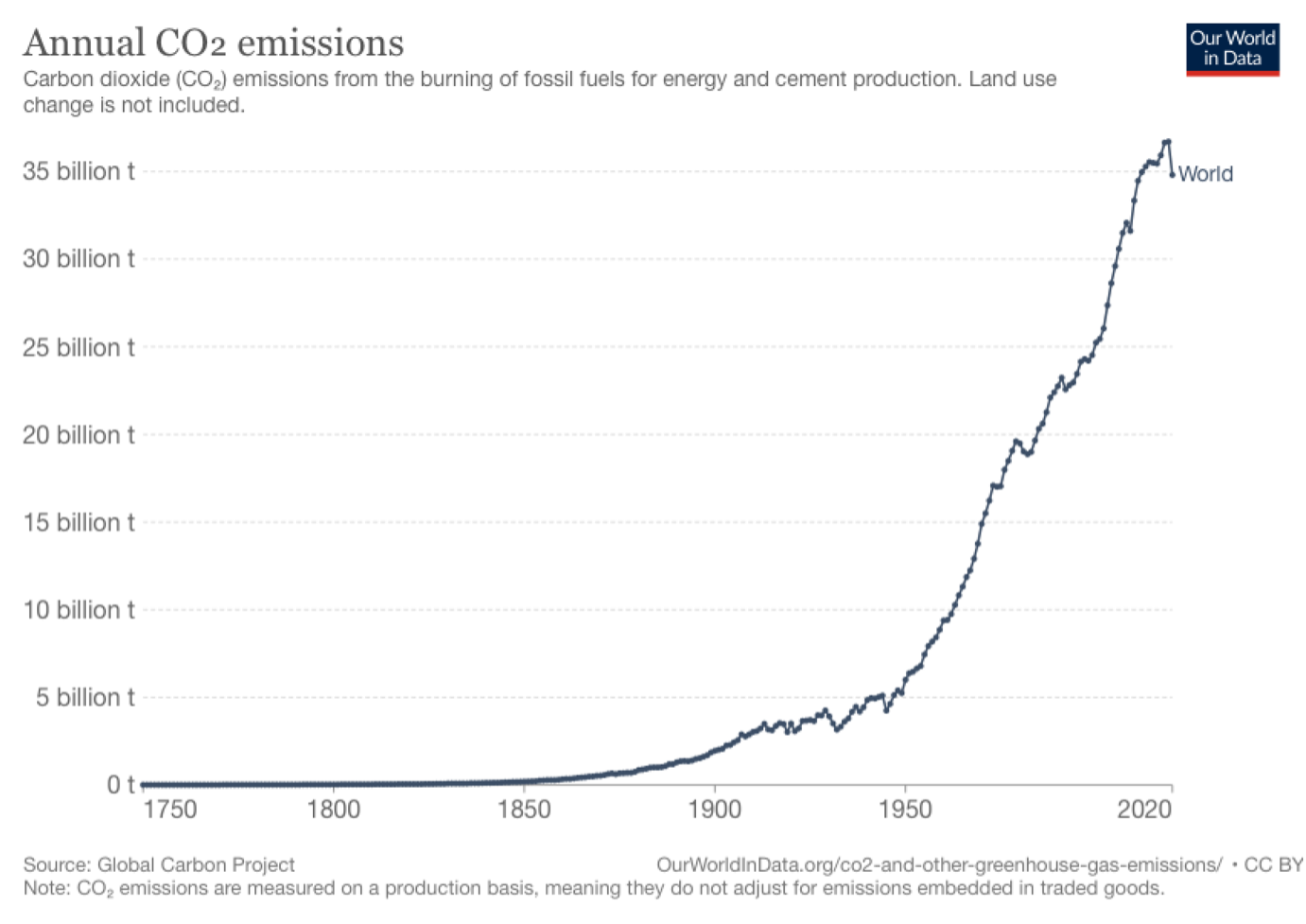

Why should we reduce emissions? This question hardly seems to be relevant anymore. Even if we still have people that do not believe in the CO2 emissions' effects on the climate, there is no doubt that the public opinion is changing. Irrespective of your personal point of view, we are all affected.

Governments are implementing taxes to reduce emissions and investors are looking for new “green” alternatives. Most major international companies have made “net zero” policies and are changing the way they invest and operate.

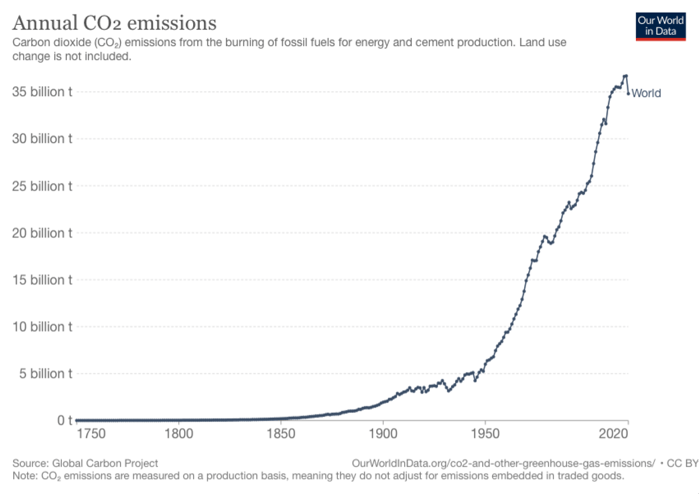

Figure source: https://ourworldindata.org/co2-emissions#licence

Figure source: https://ourworldindata.org/co2-emissions#licence

A good way of dealing with the emissions is to consider a long-term strategy as well as a short-term one. Even if the end solution is to change into a sustainable energy source, we still need to improve the way we operate - immediately.

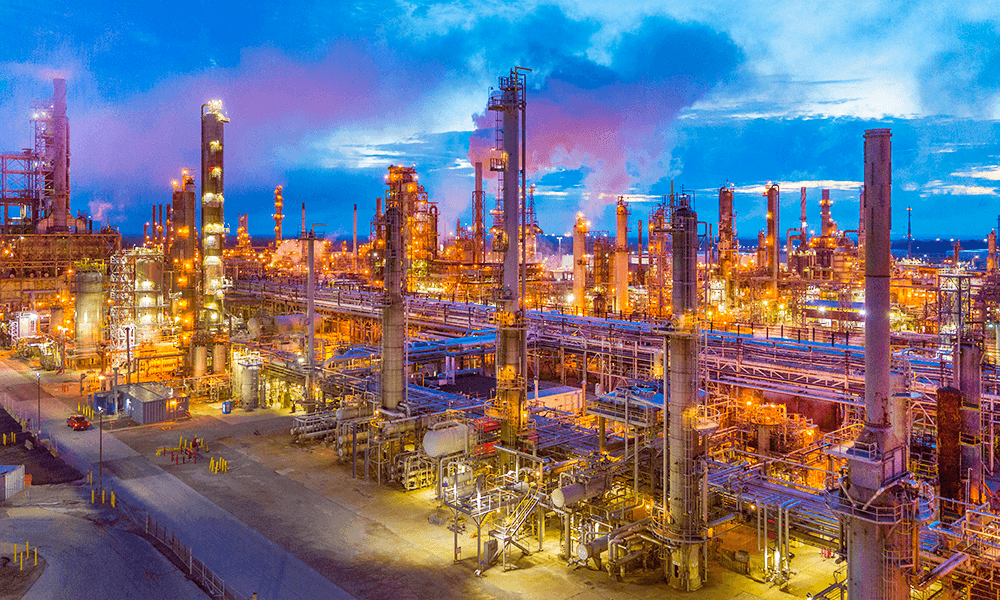

When it comes to large complex industrial sites or oil and gas installations, it is possible to reduce emissions by changing the way the plant is operated. Some of the reduced emissions may be achieved with no or low investments, simply by operating the plant with GHG (Greenhouse gas reduction) in mind.

Efficiency and safety versus low emissions

For decades we have been operating plants with a safety-first mindset, and clearly whilst we will never compromise on safety, industry spotlight is now on sustainability, reduced emissions as well as operating safely. But is the industry able to balance operational efficiency with reduced emissions? This approach may very well be possible at some sites, as GHG emissions are being taxed, it may also be the most economical solution. The key to improvement and establishing a culture for reduced emissions is increased visibility and understanding.

How can we ensure that the people are making operational decisions that affect safety, efficiency and emissions have a clear understanding of the consequences of their operational decisions?

How can we improve?

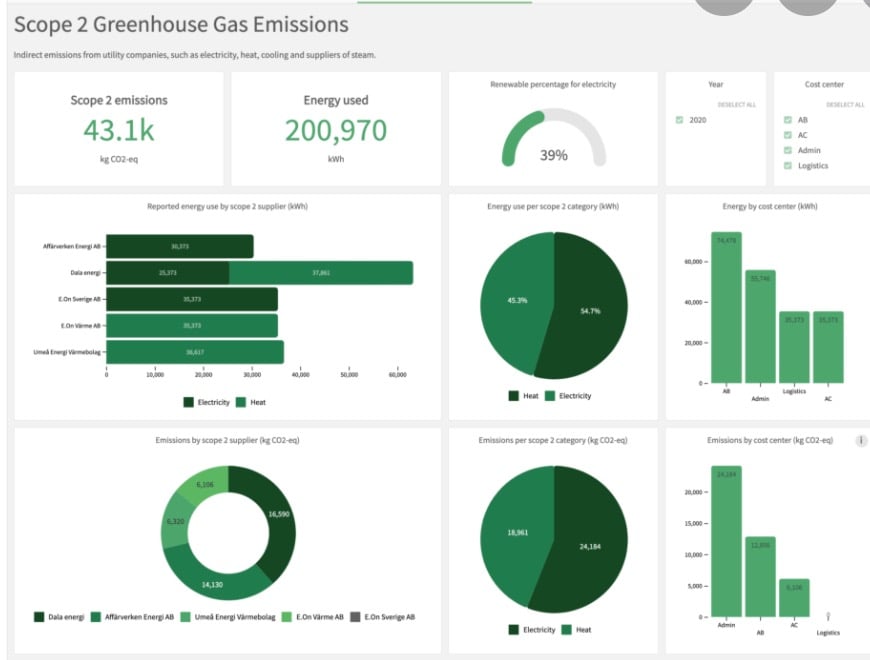

Reduced emissions are also a matter of better housekeeping; meaning how we can use the existing facilities and equipment more efficiently? This approach might sound simple and straightforward, but at industrial sites this activity is not trivial. Understanding how to operate with the lowest emissions, needs constant awareness of how emissions are changed by the current operational state.

Most operational procedures have been made with safety and production efficiency as main objectives. Now, we need to add energy efficiency into the procedures and train operational personnel accordingly. These trained operators will then know how to safely operate with the lowest possible rate of emissions and be clear on the balance between production efficiency, energy efficiency and these emissions.

There are many cases where plants are run at lower efficiency due to a lack of operational understanding or even ‘laziness’. This leads the operations team to start considering a few simple but effective operational questions such as: How does the ambient temperature affect the power output of my gas turbines? What is the operational and emissions impact of running two gas turbine process trains in parallel at a low output instead of maximizing one train?

The first steps to answering such questions is to create an understanding of the main emissions contributors by asking more questions – such as: What are the possible different ways of operating the plant? The job of operations is not completed once the plant is operating safely, there should always be a culture of continuing to try to optimize the plant, as well as looking for ways to reduce emissions.

Recommendations for operational improvements

Firstly, find and target the main contributors to emissions and subsequently establish forward-looking procedures on how to deal with the different operational modes. Secondly, discuss and ensure that there is a culture of knowing how to handle production efficiency versus emissions situations. Thirdly, ensure that there is a clear understanding on when the operation moves from an emissions and production focus into a safety concern/mode. Finally, and this one is paramount - establish KPI (Key Performance Indicators) that concentrate on safety, production, energy, and emissions.

In our view, forward-looking operational mode awareness is key and is more important than strict comparison with an optimum production figure (rear-view mode). Therefore, implementing a solution that provides such operational advice or recommendations could be a hugely valuable addition to the Control Room and for the Operators.

Helping your resources understand what to do to improve is a far better strategy for overall operational improvements at reduced GHGs.