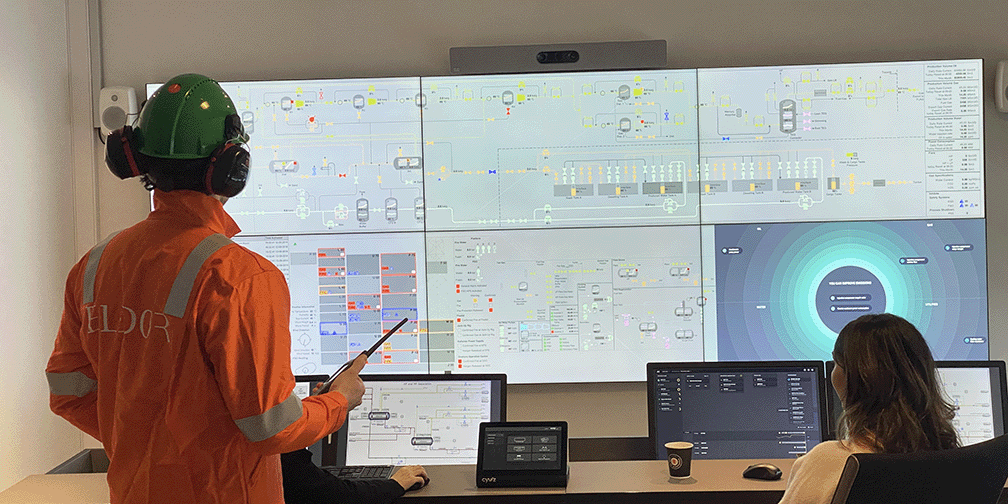

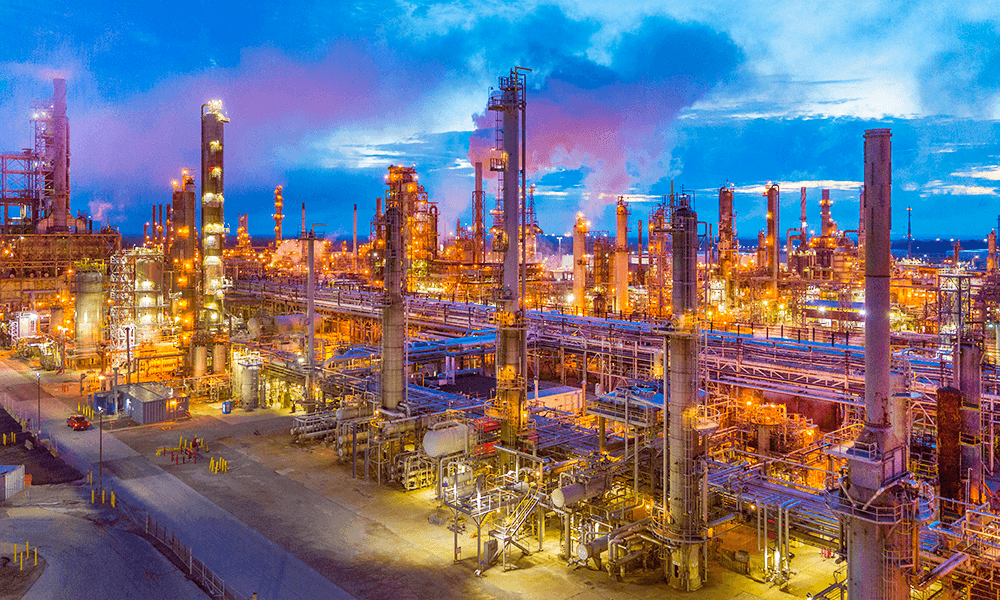

Are you the owner of a processing plant or a part of its management team? If so, then you may have experienced an energy loss problem, a common issue in many industries. Despite spending time and money on training staff to be energy-conscious, production plants often need additional help to properly manage their energy use.

Bernt Eldor

Recent posts by Bernt Eldor

3 min read

Uncovering Energy Waste in Processing Plants

By Bernt Eldor on 24/04/23 10:00

Topics: Environment Reduce emissions

3 min read

6 ways to improve the quality of HAZOPs

By Bernt Eldor on 02/02/23 11:27

If you are responsible for process safety, then you know how important it is to perform a high-quality hazard and operability study (HAZOP) analysis. HAZOPs are highly effective at identifying potential hazards and risks in industrial facilities and processes. A good HAZOP will help identify potential issues and mitigate risks before they cause problems. However, conducting a successful HAZOP requires careful planning and execution.

Topics: Root causes

4 min read

How to detect and avoid Failure Propagation in Processing Systems

By Bernt Eldor on 18/01/23 14:05

Failure propagation (and the potential severity we are facing) in processing systems is a key factor to consider when assessing the reliability and stability of any system. It can occur due to a variety of causes, such as hardware or software malfunctions, environmental factors, or user errors. The effects of failure propagation can be devastating if left unchecked, resulting in data loss, system downtime, and other costly consequences. Therefore, it's necessary to understand how failure propagates through systems so that risks can be detected and mitigated, before they become critical issues.

Topics: Root causes

3 min read

How can we build a culture for reduced emissions in the control room?

By Bernt Eldor on 21/06/22 15:09

Today there is no contradiction between sustainability and profitability. In fact, as many as 93% of CEOs think that sustainability will be an important part of their company’s future success (1 according to the 2010 UN Global Compact-Accenture CEO Study “a New era of Sustainability”), Wall Street Journal even makes a list of the 100 Most Sustainably Managed Companies in the world1.

Topics: Digitalization Reduce emissions

4 min read

5 simple ways to reduce Greenhouse Gas emissions in industrial assets

By Bernt Eldor on 18/05/22 09:17

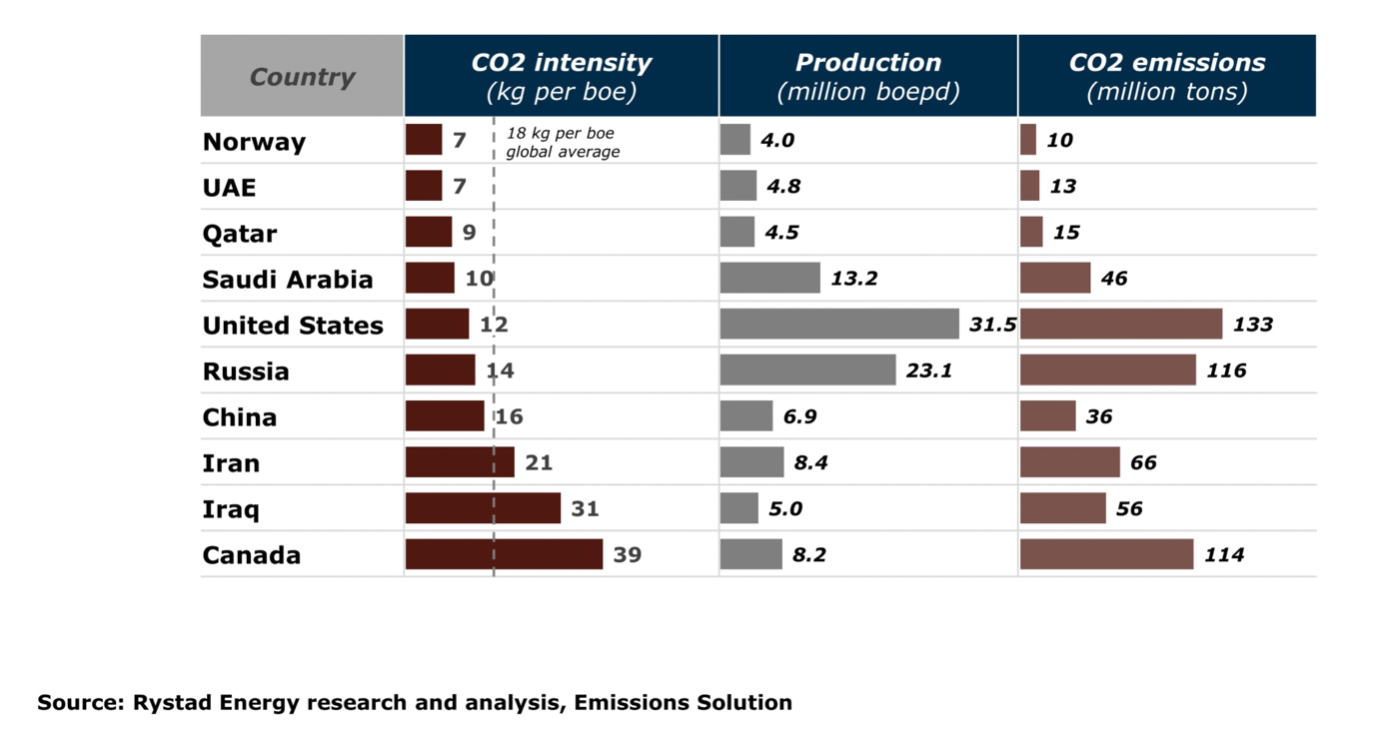

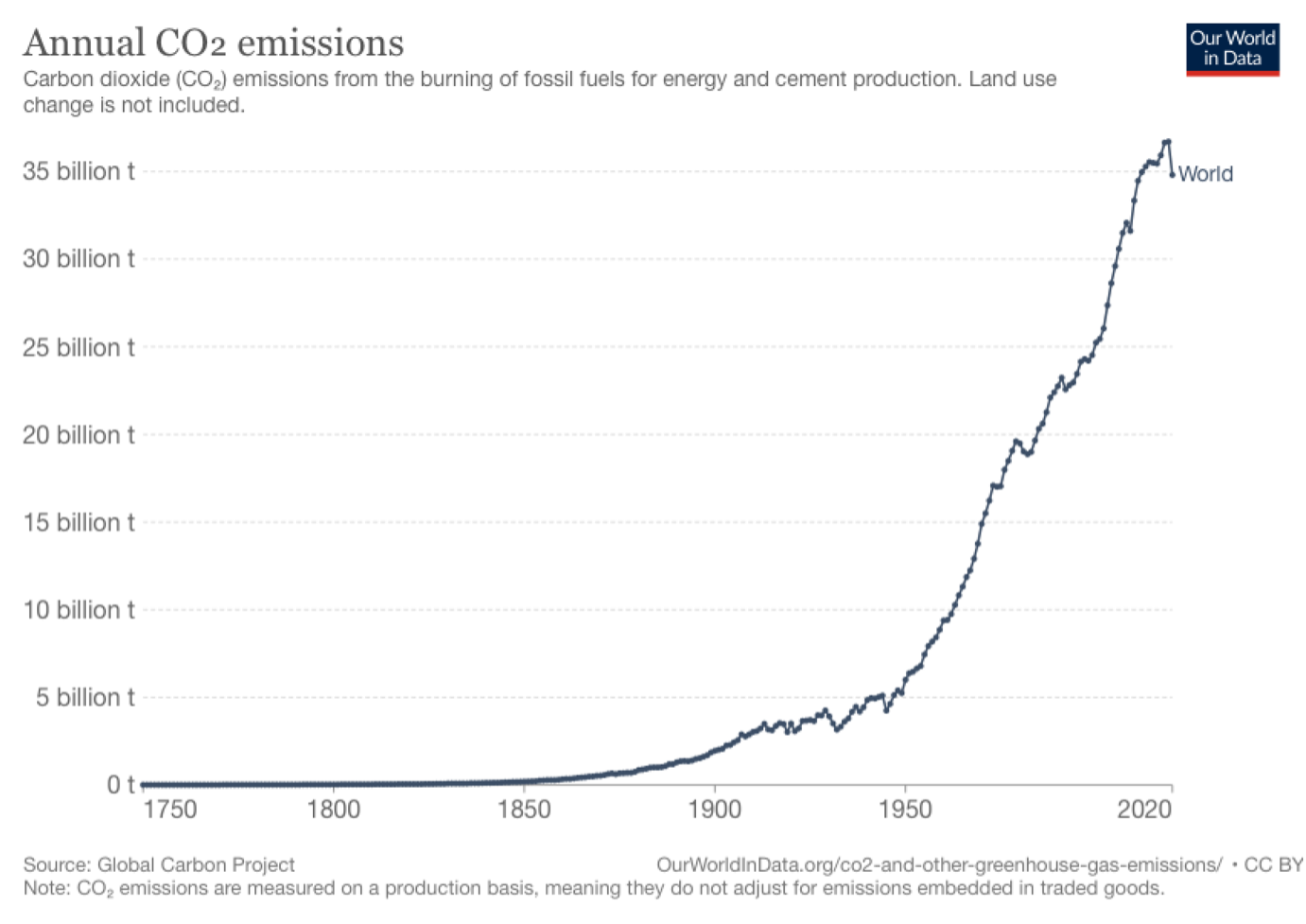

All industrial production that uses energy will be a source of Greenhouse Gas (GHG) emissions, if not entirely powered from renewable sources. Especially for upstream oil and gas production where the dominant energy source is not renewable.

Topics: Reduce emissions

3 min read

Can operation improvements lead to reduced emissions?

By Bernt Eldor on 15/03/22 10:05

Why should we reduce emissions? This question hardly seems to be relevant anymore. Even if we still have people that do not believe in the CO2 emissions' effects on the climate, there is no doubt that the public opinion is changing. Irrespective of your personal point of view, we are all affected.

Topics: Environment Reduce emissions

3 min read

Can you manage the safety integrity of changes?

By Bernt Eldor on 07/12/21 11:17

As soon as we hear the words safety, integrity and changes in combination, we start thinking about Safety Lifecycle Management or Management of Change (MoC) processes. This process is then naturally always applicable. When you work within a production facility with hazards, you have to follow different standards to ensure that your plant is always operating safely.

Topics: Root causes Safety

4 min read

What are the hidden costs of re-HAZOPs?

By Bernt Eldor on 24/11/21 14:49

Process industries are using various techniques to identify and prevent hazards. There are several different approaches to hazard identification. The many available techniques of performing hazard identifications have various features and may fit all the phases of a development project at their defined milestones.

Topics: Root causes

4 min read

What are the problems with HAZOPs?

By Bernt Eldor on 11/11/21 11:04

HAZOP is a process for performing Hazards and Operability studies that was introduced in the 1970’s. It is a valuable structured way of addressing the possible hazards and operability problems when an asset potentially operates outside its original design conditions.

.png)