If you are responsible for process safety, then you know how important it is to perform a high-quality hazard and operability study (HAZOP) analysis. HAZOPs are highly effective at identifying potential hazards and risks in industrial facilities and processes. A good HAZOP will help identify potential issues and mitigate risks before they cause problems. However, conducting a successful HAZOP requires careful planning and execution.

1. Plan and allocate enough time for the study

The HAZOP process is complex and requires considerable resources to complete. Make sure that you allocate enough time for the study and plan ahead, so all people involved in the process have sufficient time and documentation available.

It's important to involve experts from different disciplines and backgrounds who can bring their technical knowledge into the analysis. This will help ensure a comprehensive HAZOP and more accurate risk mitigation measures.

It is often beneficial to use an external HAZOP Lead to guide and facilitate a HAZOP study. The presence of a separate scribe can be especially useful as it allows the HAZOP Lead and team to focus on important aspects of the study without being distracted by the writing process. This way, you ensure that the study is conducted properly and accurately, reducing potential risks or issues associated with the work process.

2. Make sure the team is knowledgeable about the process or system under review

Experience is key when it comes to performing a HAZOP analysis. Make sure that the selected team-members have sufficient expertise in the process or system being reviewed so they can accurately identify potential hazards and risks quickly. It’s also important to make sure that everyone involved in the HAZOP process understands their individual roles and responsibilities so they can work together effectively to complete the task at hand. Good and open communication between different departments should be encouraged, as this will help ensure that all people involved are on the same page when it comes to risk mitigation measures.

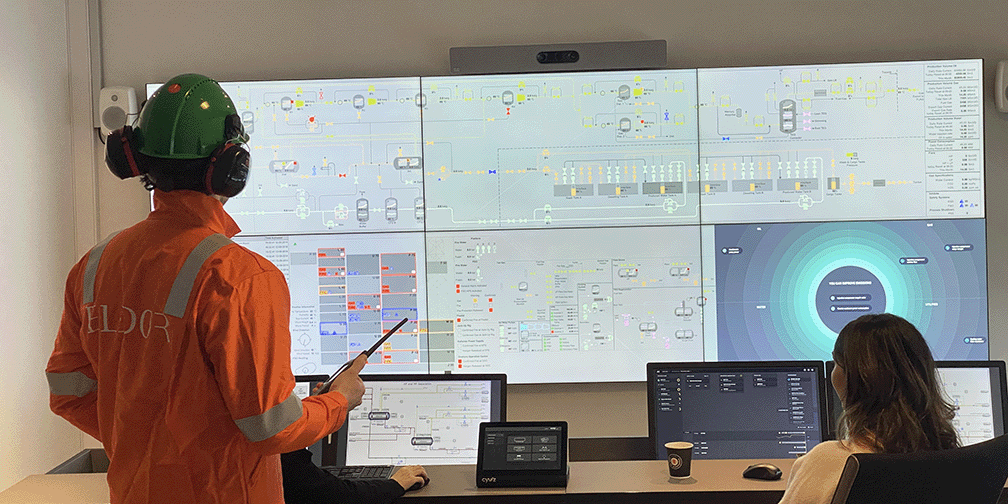

Recent technology development has led to digital twins that provide valuable insight when performing HAZOP workshops. A digital twin may include a virtual representation of a physical object or system and can also be used as knowledge on how equipment and systems should behave and be operated.

3. Use standard methodology and toolset

A standard methodology and toolset should be used when performing the HAZOP analysis. This is important to ensure that the process is carried out correctly and efficiently. All personnel involved in the process must have access to these tools so they can use them effectively during the study. Different software tools are available to facilitate a structured process where findings are properly documented for follow-up.

It's important to come with an open mind when performing a HAZOP study, as this will help avoid biased discussions, and ensure all aspects are considered. All team-members should be encouraged to voice their opinions, ideas, and concerns without fear of judgment or repercussions, as this can identify potential risk factors.

4. Review historic data

It's essential to review any relevant historic data when performing a HAZOP analysis. This will help the team identify potential areas of vulnerability, as well as provide important context and insights into the process or system under review. This can help the team make better informed decisions about risk mitigation measures. Taking advantage of data and knowledge from software solutions can add value to your HAZOP, and there are several solutions available where the classification and risk assignment is supported by twin models and AI software.

5. Be prepared to act on identified risks

A successful HAZOP study will identify potential risks and hazards that must be addressed. Action plans must be developed to address these risk factors and ensure that they are managed or eliminated where possible. This will reduce the chances of an incident occurring in the future, minimizing any potential harm or damage to personnel or property.

6. Keep records of findings

According to regulations, a record of all the findings from the HAZOP analysis must be kept for future reference. This allows for an easier review of possible changes or updates made to existing safety measures to reduce potential risks associated with a process or system. The records must also provide an accurate overview of where improvements are necessary, as well as how and when to implement them.

Summary

The key to a successful HAZOP study is preparation and forethought. Having a comprehensive plan in place, considering all relevant historic data, and encouraging an open and collaborative work-environment between team members. By following the steps above, you will ensure that your team has all the necessary resources available to them, enabling them to carry out a comprehensive analysis more efficiently and accurately. Being prepared to act on any identified risks found during the HAZOP study will also be crucial to ensuring a safe working environment for your employees.

As a result, you will help reduce the overall risk associated with the process or system under review, mitigating any potential danger to personnel or property.