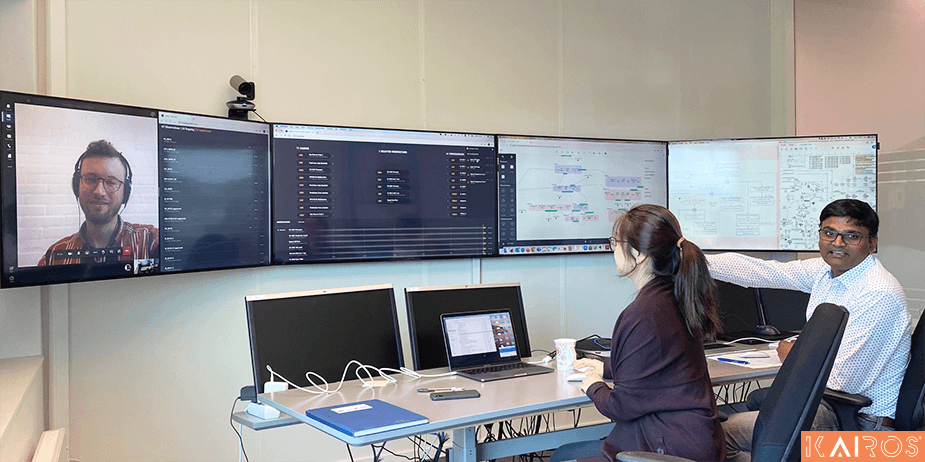

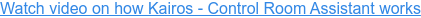

To support safe and optimal plant production Kairos - Control Room Assistant provides the control room operator with an instant status of the entire process and predicts possible causes and consequences of any system upsets in real-time.

How does the control room assistant work?

For starters, we model the goals and functions of the complex industrial system as it is designed. Together with an increasing number of clients, we have established a library of each process function based on previous models built for the industry. In these library components we have already built in the design knowledge, its objectives, and functional behaviour. This way, industry "knowhow" and valuable operational experience is kept and shared.

The Onboarding Working Process

Our onboarding process is a straight-forward 4-step process from model development to operation.

1. Model development

2. Workbench offline testing

3. Real-time implementation

4. Operation

Library for safe and effective modelling

It is easy and safe to model a new plant or system based on the plant design information, because we are using the established library blocks. The normal time to build a main process model for a medium offshore installation is now reduced to 8-12 working weeks.

Human Intelligence - The Objective trees

Kairos Technology will establish the objective trees, which is the description of the functional behaviour of the process. The functional models are built based on mass and energy flow transformations. The functional models areincorporated with process, mechanical & control design knowledge, as well as including the industry best operational experience.

Workshops - Adapting and sharing Operational Experience

We normally propose a couple of 2-4 hour workshops with the customer to discuss the prepared objective trees. We share the knowledge from other plants and adapt the objective trees to the customers' own unique operational experiences for their specific plant objective and industry knowhow.

Validation and Familiarization

Kairos Technology builds the model and uses our Scenario Maker to simulate the process behavior of the model. Test scenarios will be agreed on and performed to see the outcome and verify the model and plant design before implementation. The Scenario Maker can also be used to train operators on process disturbances and its cause/consequences.

Implementing Real-Time Data

When the model is verified, it will be connected to the plant and run with real-time data via standard OPC UA interface.

By this point you are ready and Kairos - Control Room Assistant is helping your operators make better decisions for the plant.

System maintenance of Kairos will be minimal as Kairos adapts to site data and parameter settings of the plant. Major plant modifications will be taken into account through the usual Management of Change process.