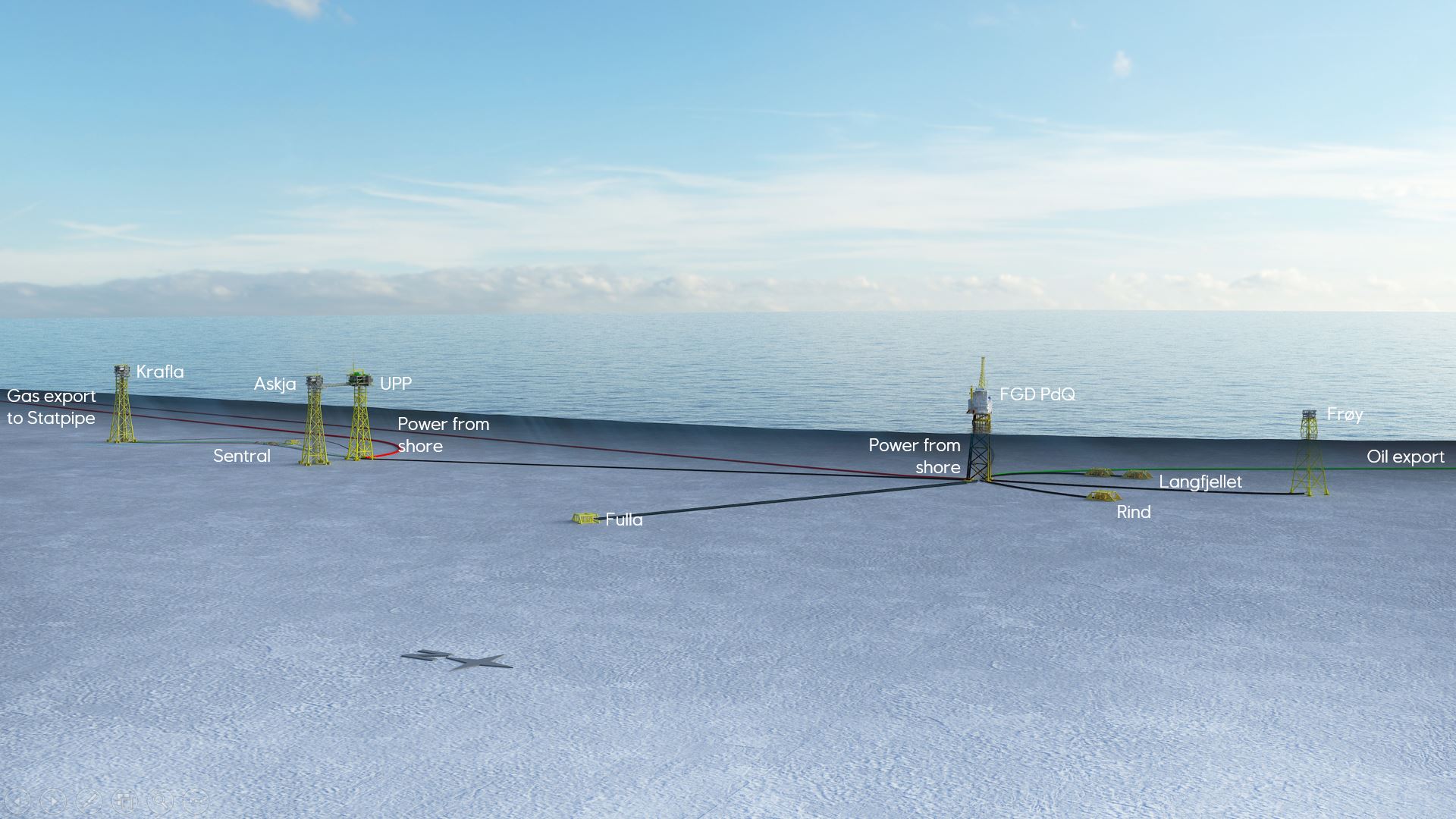

We are happy to announce that Kairos Technology has entered into an agreement with Equinor to utilize our Multilevel Flow Modelling technology during the early design phase of the Krafla development project. Krafla will be the first unmanned production platform on the Norwegian Continental Shelf.

1 min read

Kairos will support Equinor Krafla development project

By Ida Eldor on 06/09/21 08:43

Topics: @controlroomassistant Production optimization

1 min read

New contract with Semco Maritime

By Bernt Eldor on 27/04/21 08:51

We are proud to announce that Semco Maritime has selected Kairos Technology for a pre-study to develop the next generation of AI driven predictive maintenance.

Topics: @controlroomassistant Offshore Wind

2 min read

Kairos Technology in 2020

By Bjarne André Asheim on 16/12/20 08:57

Entering the last weeks before Christmas break, we are closing in to the end of 2020, which has been a challenging and exciting year for Kairos Technology. Among all, the outbreak of Covid-19 has affected all of us, yet we have managed to minimize the impact and adopted new working methods and tools to secure the commitment and engagement with our customers and the market. Our product development is on track according to plans and new exciting projects are initiated.

Topics: @controlroomassistant hazopassistant

1 min read

Webinar: How to detect production issues early and avoid losses

By Ivan Rott on 01/12/20 09:11

In this webinar, Denis Kirchhübel (Application scientist, PhD at Kairos Technology) will present a new, real user case of a gaslift compressor incident.

Topics: @controlroomassistant Webinar

Webinar: How industrial SW can prevent shutdowns, improve production efficiency, and save energy

By Ivan Rott on 29/10/20 09:33

Join our webinars to get insight into a user case where we explain how industrial software can prevent shutdowns, improve production efficiency, decrease emissions, and save energy.

Topics: @controlroomassistant Webinar

Webinar: How new technology improves plant performance

By Ida Eldor on 15/10/20 15:32

Join our webinar to see why Repsol, Equinor, Total, and Chrysaor have decided to use Kairos!

Topics: @controlroomassistant Webinar

2 min read

Equinor continues with the Control Room Assistant for Johan Castberg

By Bernt Eldor on 13/08/20 09:24

Last week, Equinor decided to move forward into phase two with Kairos Control Room Assistant for the Johan Castberg field. Despite challenges with the Covid-19 situation, the project has managed to stay on track and deliver to expectations. The project has adapted to the new situation quickly and found a good way to interact via Teams. To improve the workshops of modelling, a new software tool that supports the creation of fault scenarios has been developed. This tool will be used interactively to test, demonstrate, and explain the behavior of the model, including the Artificial Intelligence in the Control Room Assistant.

Topics: @controlroomassistant Digitalization Production optimization

3 min read

Is Kairos the right AI product for you?

By Ivan Rott on 14/07/20 09:03

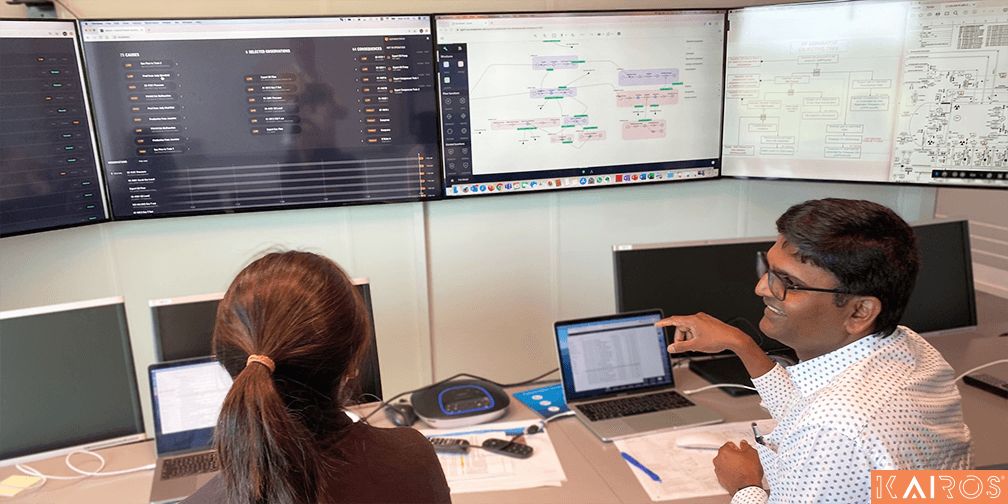

To support safe and optimal plant production, Kairos - Control Room Assistant runs in real-time as an assistant always on the alert. With live plant data as evidence, the model presents an instantaneous HAZOP with root causes, predicted consequences, and counteraction plans to assist and help the Control Room Operator.

Topics: @controlroomassistant Production optimization

3 min read

How human intelligence gets Kairos up and running on your plant faster

By Ivan Rott on 30/06/20 10:00

To support safe and optimal plant production Kairos - Control Room Assistant provides the control room operator with an instant status of the entire process and predicts possible causes and consequences of any system upsets in real-time.

How does the control room assistant work?

For starters, we model the goals and functions of the complex industrial system as it is designed. Together with an increasing number of clients, we have established a library of each process function based on previous models built for the industry. In these library components we have already built in the design knowledge, its objectives, and functional behaviour. This way, industry "knowhow" and valuable operational experience is kept and shared.

The Onboarding Working Process

Our onboarding process is a straight-forward 4-step process from model development to operation.

1. Model development

2. Workbench offline testing

3. Real-time implementation

4. Operation

Library for safe and effective modelling

It is easy and safe to model a new plant or system based on the plant design information, because we are using the established library blocks. The normal time to build a main process model for a medium offshore installation is now reduced to 8-12 working weeks.

Human Intelligence - The Objective trees

Kairos Technology will establish the objective trees, which is the description of the functional behaviour of the process. The functional models are built based on mass and energy flow transformations. The functional models areincorporated with process, mechanical & control design knowledge, as well as including the industry best operational experience.

Workshops - Adapting and sharing Operational Experience

We normally propose a couple of 2-4 hour workshops with the customer to discuss the prepared objective trees. We share the knowledge from other plants and adapt the objective trees to the customers' own unique operational experiences for their specific plant objective and industry knowhow.

Validation and Familiarization

Kairos Technology builds the model and uses our Scenario Maker to simulate the process behavior of the model. Test scenarios will be agreed on and performed to see the outcome and verify the model and plant design before implementation. The Scenario Maker can also be used to train operators on process disturbances and its cause/consequences.

Implementing Real-Time Data

When the model is verified, it will be connected to the plant and run with real-time data via standard OPC UA interface.

By this point you are ready and Kairos - Control Room Assistant is helping your operators make better decisions for the plant.

System maintenance of Kairos will be minimal as Kairos adapts to site data and parameter settings of the plant. Major plant modifications will be taken into account through the usual Management of Change process.